-

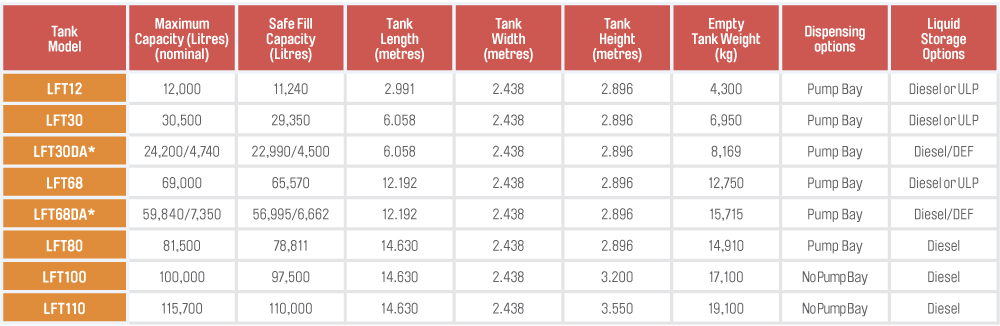

Multiple storage sizes ranging from 12,000 L to 115,700 L

-

Built to UL142, AS1940, AS1692, AS1657

-

Durable, modular and robust design

-

Greater usable fuel volume than many other tanks

-

Approved to safely store and dispense Diesel, AdBlue, Diesel /AdBlue, ULP, Aviation, Oil & other petrochemicals

-

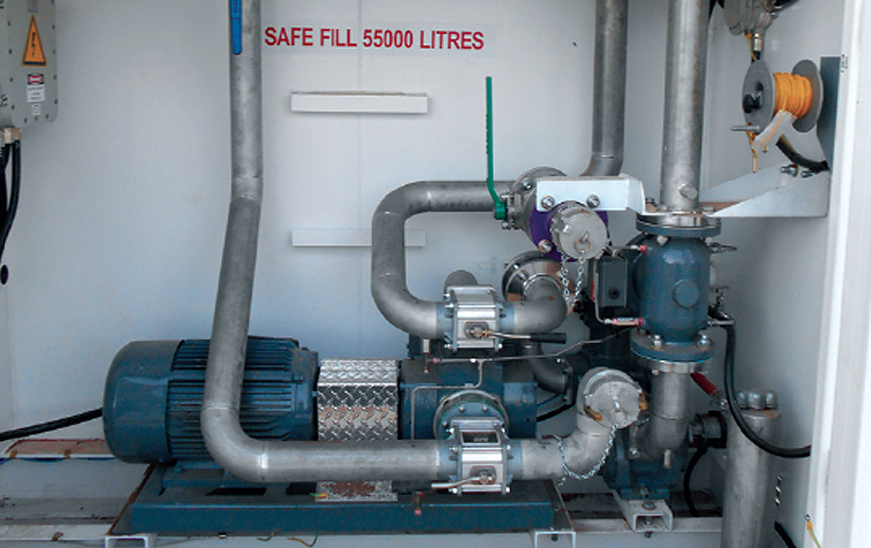

Pumping solutions: 40 – 800 L/pm

-

Fuel Management Packages also can be fitted

HOST ISO Classic SBTs

The HOST ISO Classic range of Self Bunded Storage tanks are the result of listening to our customers and investing a great deal of engineering resources to design robust and high quality tank packages that provide more economical solutions for bulk liquid storage.

HOST ISO Classics can be used as:

-

Single tanks or multi-million litre tank farms

-

Are ISO container design based on 10, 20, 40 and 48 foot specifications for ease of transportation

-

Designed to hold and dispense diesel, ULP, oils, aviation fuel, AdBlue (DEF) and many other petrochemicals.

-

Ideally suited for use in industries such as: fuel distribution, mining, aviation, power generation, oil and gas, military, transport and construction.

The range builds upon acquired knowledge and experiences and include key features that deliver you huge benefits, such as:

-

Clean rounded lines on the inner tank eliminate stress points and areas for contamination to collect

-

Floor drains to a low point at the front of the tank for water removal

-

All tanks are intermodal. Standard containers can be transported by standard trucks or trains and moved by shipping container handling equipment, without cranes.

Whether it’s store a dangerous good or a highly flammable liquid the ISO Classic range is founded on delivering ultimate safety.

-

Tanks are certified and tested to the highest global standards for bulk fuel storage, UL142, these tanks exceed all relevant Australian Standards for storage of flammable and combustible liquids

-

When empty, the tank is also an approved, truly intermodal container as classified by CSC to IMO standards.

-

They are also manufactured to meet the Australian standards, AS1940, AS1692, and AS1657 and are all Australian designed and Australian certified. A valuable feature if an emergency ever arises.

HOST ISO Classics – Tank Sizes

Gallery

A stack more in every tank

Key features of every HOST ISO Classic SBT

-

All tanks are built to UL approval (PLUS AS1940, AS1692, AS1657 (A heavier duty design and structure than the Australian Standard).

-

All tanks have rounded corners on both the top and bottom of the tank, providing extra strength in the construction and more importantly does not allow debris or water pooling in the corners or the bottom of the tank.

-

These tanks have sloping floors (from the back to the front and from the sides to the middle). It ensures all water is pooling at the water well. Flat bottom tanks do not provide this benefit, this can result in water pooling and algae growth in the tank, potentially leading to a contaminated product. The water well has a suction tube installed for removal of water through the top of the tank.

-

Tanks come standard with emergency vents on the primary tank and interstitial section or bunded part.

-

All tanks are designed to be viewed from underneath as per AS1940 and more importantly to provide air flow to the base of the tank. The tank floor is elevated off the ground and is open at the sides allowing visual inspection and air flow to prevent moisture build up, which promotes corrosion on the bottom of the tank. Standard flat tanks don’t allow this type of airflow to naturally occur.

-

Overfill valve, Anti-syphon valves and High Level Alarms are supplied as standard on all tanks.

-

The fill line has a standard stainless steel 80 mm Isolation valve and Check valve fitted.

-

All tanks come with an Anodised Dipstick.

-

The pressure or suction pipe is fitted with an 80 mm Isolation valve.

-

The tanks roof is designed to cascade water off its surface, reducing corrosion.

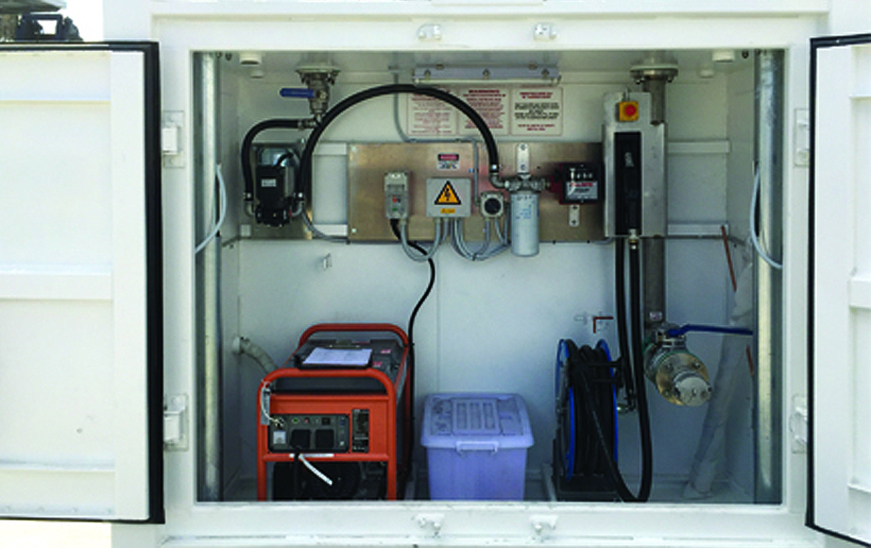

Need your tank fitted and ready to dispense? Our distributors all offer complete turn key solutions. Standard Self Bunded Bulk Liquid Storage Tank dispensing packages can be designed to include:

PUMPS

-

Light Vehicle – 80 L/pm

-

Heavy Vehicle or high flow – 160 L/pm

-

Mining Equipment – 800 L/pm

-

AdBlue Solution Pump – On tank and Off Tank

-

Ebsray Unloading Pump – up to 1000 L/pm

FUEL MANAGEMENT SYSTEMS

-

SmartFill, Piusi, Compac, Transponder and others

-

White Card / Company Cards

-

CCDCA (Credit Cards)

-

Remote Reporting via Web (No Fees)

TANK GAUGES

-

OPW Nano Tank Gauging

-

Remote viewing of tank volumes

-

High and Low Alarms

METERS

-

Electronic or Mechanical Registers

-

TCS meters or others

BULK DISPENSING EQUIPMENT

-

Liquip Loading Arms – up to 1800 L/pm)

-

Liquip Control Consoles and Metering

-

Liquip Over Fill Control Systems

-

Liquip Dead Man Switch